Rapid water chillers

Indirect water chillers

Feeding the mixer with chilled water ensures that the dough is always at the desired final temperature, regardless of the external ambient conditions. The separated refrigerated circuit of the rapid water chillers ensures the maximum hygiene and reduced power consumption.

Chilled water for high-quality dough

Feeding the mixer with chilled water ensures that the dough is always at the desired final temperature, regardless of the external ambient conditions. This allows to obtain a consistently high-quality end product at all times, even through the use of automatic equipment.

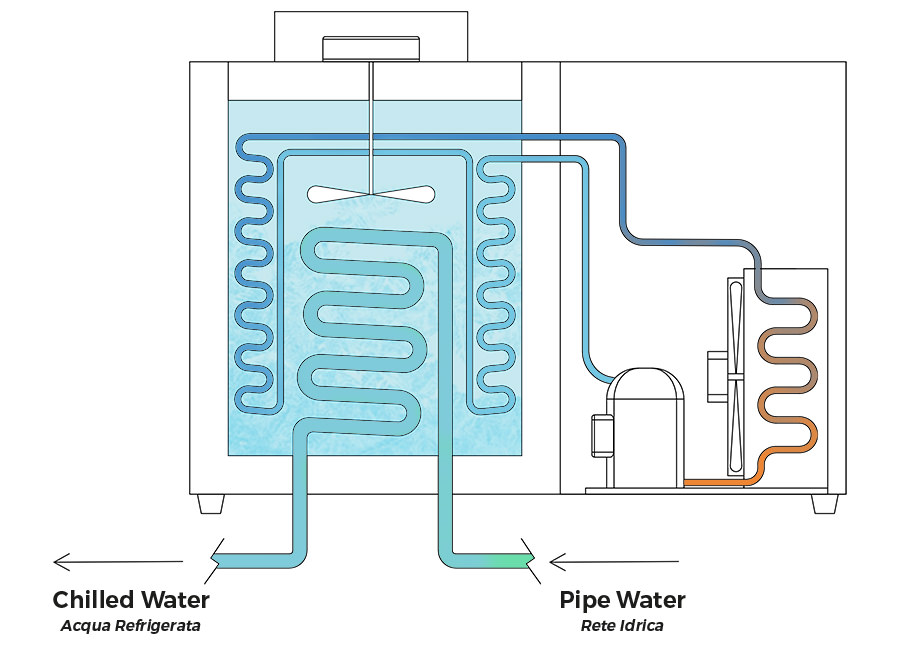

Indirect refrigeration system

The refrigerating circuit cools down water stored inside a tank, bringing its temperature to 0°C to partially freeze it. The actual water to be refrigerated for usage flows inside a coil immersed in this tank with 0 °C water and ice, thus quickly cooling itself as it flows. This system allows to cool down the water to be used while always keeping it inside a separated circuit, thus preventing possible water contamination risks.

Rapid water chiller advantages

Compact

Reduced in volume and can be hang to the wall

Maximum hygiene

The water flows inside a separated circuit

Energy savings

No pump required as it uses only the aqueduct pressure

Available models

The rapid water chillers model available differ for the maximum chilled water quantity they can supply in a single unloading. Between two successive unloadings it is required to wait 15 minutes, to allow time for the water inside the tank to cool down to 0 °C again.

The hourly production is calculated considering the 4 unloadings that are possible in one hour. All values shown in the table refer to a water of +18°C being cooled down to +3°C with an environment temperature of +32°C.

Technical data

| Model | Max water quantity unloaded in a single discharge [lt] | Wait time between water discharges [min] | Hourly production rate [lt/h] | Width L [cm] | Depth P [cm] | Height H [cm] | Compressor power [hp] | Maximum absorbed power [kW] | Voltage [Volt/F/Hz] |

|---|---|---|---|---|---|---|---|---|---|

| RR-60 | 15 | 15 | 60 | 75 | 53 | 62 | 0.5 | 0.8 | 230/1/50 |

| RR-100 | 25 | 15 | 100 | 75 | 53 | 62 | 1.0 | 1.2 | 230/1/50 |

| RR-160 | 40 | 15 | 160 | 85 | 55 | 65 | 1.5 | 1.8 | 400/3/50 |

| RR-240 | 60 | 15 | 240 | 85 | 60 | 112 | 2.2 | 2.6 | 400/3/50 |

| RR-300 | 75 | 15 | 300 | 85 | 60 | 112 | 3.0 | 3.3 | 400/3/50 |

| RR-500 | 125 | 15 | 500 | 85 | 60 | 112 | 5.0 | 5.5 | 400/3/50 |

Technical features

Our proofers are at your disposal!

You can come to our headquarter and try your recipes working with a laboratory 4.0!

Fill out the form, you will be contacted in no time!