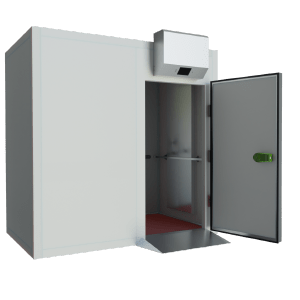

Easypan Series

Retarder Proofers for 2 or more trolleys

Modular Retarder Proofers available in a wide range of dimensions and configurations, ideal to control the proofing of bakery and pastry products. By managing temperature and humidity the leavening process can be slowed down, to allow the baker to prepare it during the day and find it perfectly leavened and ready for baking the next morning.

Controls

Temperature

Humidity

Duration

Fans speed

Retarder Proofer advantages

No more night-time work

The product can be prepared during the day and put into the retarder proofer, to get it the next morning perfectly leavened and ready for baking at the desired time

Higher and constant product quality

The productive process becomes repeatable and is not influenced by the environment temperature

Cost reduction

Thanks to the optimization of personnel use and the increased standardization of the productive process

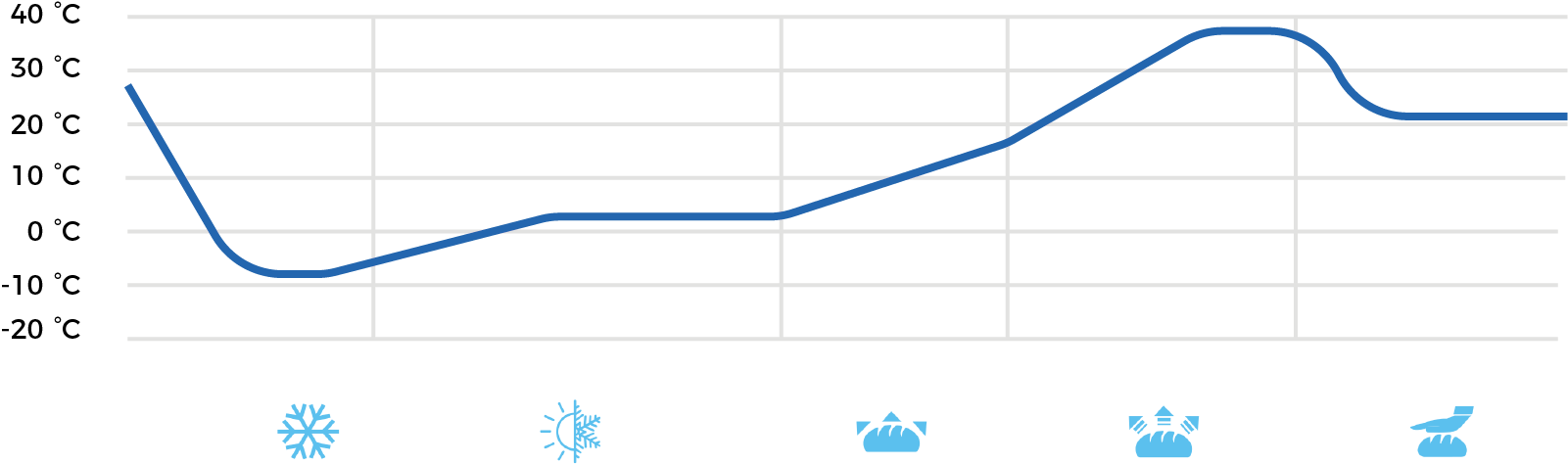

Retarder Proofer cycle

Thanks to its humidity and temperature control, the Retarder Proofer cycle allows with its 4(+1) separate phases to delay and control the leavening process and obtain a perfectly leavened product at the desired time.

Chilling

Rapid cooling to block yeast activity

Conservation

The product is kept at low temperature, the rising process is still suspended

Reawakening

The temperature begins to slowly rise, the rising process restarts

Rising

The proofer slowly reaches the set temperature and humidity, the rising process is completed

Rising block

Optional step to block the rising once again by reducing the temperature, useful to keep the product ready for baking at a later time

Flexible and Multifunctional

Thanks to the flexibility of its control panel, it can be used as:

- Retarder Proofer

- Fermentation Chamber

- Refrigeration/Conservation Unit

- Defrosting Chamber

This versatility allows the proofer to be utilized 24/7, thus ensuring a quick return on investment.

Gentle and Uniform Air Flow

The ventilation system is seamlessly integrated into the chamber and is designed to ensure consistent humidity and temperature in every position inside the proofer.

Easypan Series Features

- 80 mm insulation panels thickness

- White zinc-plasticized interior finish

- White zinc-plasticized exterior finish (stainless steel upon request)

- Carriageable Floor 60 mm thickness in high-resistance phenolic resin, with a rough non-slip surface

- Stainless Steel AISI 316 Steam Accumulation Generator with heating elements

- Tropicalized refrigeration unit

7” touch screen control panel for Industry 4.0

New 7" capacitive high-definition touch screen, with simple and intuitive programming. Equipped with Alaska LEV4 Software featuring:

- Set and current values always displayed

- Manual mode for Chilling, Conservation, Rising and Rising block

- Automatic mode with complete Retarder Proofing cycles, customisable in each phase

- Programmable start and finish cycle times

- Tabular and graphical HACCP log with temperature and humidity history, downloadable on USB

- Wifi for interconnection with Turri Group Web Platform

Types of Doors

Single door

Double door with central post

Double door without central post

Sliding door

Tunnel structure

Easypan Industry

Alaska has always been a specialist in creating customized solutions based on the customer's specific needs and available space.

The Easypan series is designed to be easily manufactured in dimensions and configurations beyond those listed in the catalog, to meet every production need, including those of the most industrial clients.

Technical data

| Model | External width L [cm] | External depth P [cm] | Door Open Depth W [cm] | Useful Internal Width Li [cm] | Useful Internal Depth Pi [cm] | Doorway L1xH1 [cm] | Rack capacity for 40×60 trays | Rack capacity for 60×80 trays | Rack capacity for 60×80 trays C&G | Rack capacity for 80×80 trays | Rack capacity for 80×120 trays | Rack capacity for 63×180 frames (L=125) | Rack capacity for 63×215 frames (L=160) | Rack capacity for 63×255 frames (L=200) | Rack capacity for 63×297 frames (L=242) | Maximum absorbed power [kW] | Compressor Power (&) [Hp] | Power Supply Voltage [Volt/F/Hz] | Quantità prodotto (*) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EP 111525 | 119 | 159 | 251 | 83 | 140 | 79×200 | 2 | 1 | 1 | – | – | – | – | – | – | 2,9 | 1,1E | 230/1/50 | 100 |

| EP 111725 | 119 | 179 | 271 | 83 | 160 | 79×200 | 3 | 1 | 1 | – | – | – | – | – | – | 2,9 | 1,1E | 230/1/50 | 100 |

| EP 111925 | 119 | 199 | 291 | 83 | 180 | 79×200 | 3 | 2 | 1 | – | – | 1 | – | – | – | 2,9 | 1,1E | 230/1/50 | 100 |

| EP 112125 | 119 | 219 | 311 | 83 | 200 | 79×200 | 4 | 2 | 2 | – | – | 1 | – | – | – | 2,9 | 1,25E | 230/1/50 | 120 |

| EP 112325 | 119 | 239 | 331 | 83 | 220 | 79×200 | 4 | 2 | 2 | – | – | 1 | 1 | – | – | 5,8 | 1,5E | 400/3/50 | 150 |

| EP 112525 | 119 | 259 | 351 | 83 | 240 | 79×200 | 4 | 2 | 2 | – | – | 1 | 1 | – | – | 5,8 | 1,5E | 400/3/50 | 160 |

| EP 112725 | 119 | 279 | 371 | 83 | 260 | 79×200 | 5 | 3 | 2 | – | – | 1 | 1 | 1 | – | 5,8 | 1,5E | 400/3/50 | 180 |

| EP 113125 | 119 | 319 | 411 | 83 | 300 | 79×200 | 6 | 3 | 3 | – | – | 1 | 1 | 1 | 1 | 5,8 | 2# | 400/3/50 | 210 |

| EP 113325 | 119 | 339 | 431 | 83 | 320 | 79×200 | 6 | 3 | 3 | – | – | 1 | 1 | 1 | 1 | 5,9 | 2# | 400/3/50 | 210 |

| EP 113725 | 119 | 379 | 471 | 83 | 360 | 79×200 | 7 | 4 | 3 | – | – | 1 | 1 | 1 | 1 | 6,1 | 2,5# | 400/3/50 | 250 |

| Model | External width L [cm] | External depth P [cm] | Door Open Depth W [cm] | Useful Internal Width Li [cm] | Useful Internal Depth Pi [cm] | Doorway L1xH1 [cm] | Rack capacity for 40×60 trays | Rack capacity for 60×80 trays | Rack capacity for 60×80 trays C&G | Rack capacity for 80×80 trays | Rack capacity for 80×120 trays | Rack capacity for 63×180 frames (L=125) | Rack capacity for 63×215 frames (L=160) | Rack capacity for 63×255 frames (L=200) | Rack capacity for 63×297 frames (L=242) | Maximum absorbed power [kW] | Compressor Power (&) [Hp] | Power Supply Voltage [Volt/F/Hz] | Quantità prodotto (*) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EP 131525 | 139 | 159 | 266 | 103 | 140 | 94×200 | 4 | 2 | 1 | 1 | 1 | – | – | – | – | 2,9 | 1,1E | 230/1/50 | 100 |

| EP 131725 | 139 | 179 | 289 | 103 | 160 | 94×200 | 4 | 2 | 1 | 1 | 1 | – | – | – | – | 2,9 | 1,1E | 230/1/50 | 100 |

| EP 131925 | 139 | 199 | 306 | 103 | 180 | 94×200 | 5 | 2 | 1 | 2 | 1 | 1 | – | – | – | 2,9 | 1,1E | 230/1/50 | 100 |

| EP 132125 | 139 | 219 | 326 | 103 | 200 | 94×200 | 6 | 2 | 2 | 2 | 1 | 1 | – | – | – | 2,9 | 1,25E | 230/1/50 | 120 |

| EP 132325 | 139 | 239 | 346 | 103 | 220 | 94×200 | 6 | 3 | 2 | 2 | 1 | 1 | 1 | – | – | 5,8 | 1,5E | 400/3/50 | 150 |

| EP 132525 | 139 | 259 | 366 | 103 | 240 | 94×200 | 6 | 3 | 2 | 2 | 1 | 1 | 1 | – | – | 5,8 | 1,5E | 400/3/50 | 160 |

| EP 132725 | 139 | 279 | 386 | 103 | 260 | 94×200 | 8 | 3 | 2 | 3 | 2 | 1 | 1 | 1 | – | 5,8 | 1,5E | 400/3/50 | 180 |

| EP 133125 | 139 | 319 | 426 | 103 | 300 | 94×200 | 8 | 4 | 3 | 3 | 2 | 1 | 1 | 1 | 1 | 5,8 | 2# | 400/3/50 | 210 |

| EP 133325 | 139 | 339 | 446 | 103 | 320 | 94×200 | 9 | 4 | 3 | 3 | 2 | 1 | 1 | 1 | 1 | 5,9 | 2# | 400/3/50 | 210 |

| EP 133725 | 139 | 379 | 486 | 103 | 360 | 94×200 | 10 | 5 | 3 | 4 | 2 | 1 | 1 | 1 | 1 | 6,1 | 2,5# | 400/3/50 | 250 |

| Model | External width L [cm] | External depth P [cm] | Door Open Depth W [cm] | Useful Internal Width Li [cm] | Useful Internal Depth Pi [cm] | Doorway L1xH1 [cm] | Rack capacity for 40×60 trays | Rack capacity for 60×80 trays | Rack capacity for 60×80 trays C&G | Rack capacity for 80×80 trays | Rack capacity for 80×120 trays | Rack capacity for 63×180 frames (L=125) | Rack capacity for 63×215 frames (L=160) | Rack capacity for 63×255 frames (L=200) | Rack capacity for 63×297 frames (L=242) | Maximum absorbed power [kW] | Compressor Power (&) [Hp] | Power Supply Voltage [Volt/F/Hz] | Quantità prodotto (*) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EP 171525 | 179 | 159 | 266 | 143 | 140 | 94×200 | 4 | 2 | 2 | 1 | 1 | – | – | – | – | 5,8 | 1,5E | 400/3/50 | 150 |

| EP 171725 | 179 | 179 | 289 | 143 | 160 | 94×200 | 6 | 3 | 2 | 1 | 1 | – | – | – | – | 5,8 | 1,5E | 400/3/50 | 150 |

| EP 171925 | 179 | 199 | 306 | 143 | 180 | 94×200 | 6 | 4 | 2 | 2 | 2 | 2 | – | – | – | 5,8 | 2# | 400/3/50 | 180 |

| EP 172125 | 179 | 219 | 326 | 143 | 200 | 94×200 | 8 | 4 | 4 | 2 | 2 | 2 | – | – | – | 5,8 | 2# | 400/3/50 | 200 |

| EP 172325 | 179 | 239 | 346 | 143 | 220 | 94×200 | 8 | 4 | 4 | 2 | 2 | 2 | 2 | – | – | 9,2 | 3# | 400/3/50 | 240 |

| EP 172525 | 179 | 259 | 366 | 143 | 240 | 94×200 | 8 | 5 | 4 | 2 | 2 | 2 | 2 | – | – | 9,2 | 3# | 400/3/50 | 260 |

| EP 172725 | 179 | 279 | 386 | 143 | 260 | 94×200 | 10 | 6 | 5 | 2 | 2 | 2 | 2 | 2 | – | 11,4 | 3# | 400/3/50 | 300 |

| EP 173125 | 179 | 319 | 426 | 143 | 300 | 94×200 | 12 | 6 | 6 | 3 | 3 | 2 | 2 | 2 | 2 | 11,5 | 4# | 400/3/50 | 300 |

| EP 173325 | 179 | 339 | 446 | 143 | 320 | 94×200 | 12 | 6 | 6 | 3 | 3 | 2 | 2 | 2 | 2 | 11,5 | 4# | 400/3/50 | 360 |

| EP 173725 | 179 | 379 | 486 | 143 | 360 | 94×200 | 14 | 8 | 7 | 4 | 4 | 2 | 2 | 2 | 2 | 11,6 | 4# | 400/3/50 | 400 |

| Model | External width L [cm] | External depth P [cm] | Door Open Depth W [cm] | Useful Internal Width Li [cm] | Useful Internal Depth Pi [cm] | Doorway L1xH1 [cm] | Rack capacity for 40×60 trays | Rack capacity for 60×80 trays | Rack capacity for 60×80 trays C&G | Rack capacity for 80×80 trays | Rack capacity for 80×120 trays | Rack capacity for 63×180 frames (L=125) | Rack capacity for 63×215 frames (L=160) | Rack capacity for 63×255 frames (L=200) | Rack capacity for 63×297 frames (L=242) | Maximum absorbed power [kW] | Compressor Power (&) [Hp] | Power Supply Voltage [Volt/F/Hz] | Quantità prodotto (*) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EP 211525 | 219 | 159 | 266 | 183 | 140 | 94×200 | 6 | 4 | 2 | 2 | 2 | – | – | – | – | 5,8 | 1,5E | 400/3/50 | 150 |

| EP 211725 | 219 | 179 | 289 | 183 | 160 | 94×200 | 8 | 4 | 3 | 2 | 2 | – | – | – | – | 5,8 | 1,5E | 400/3/50 | 150 |

| EP 211925 | 219 | 199 | 306 | 183 | 180 | 94×200 | 8 | 4 | 2 | 4 | 2 | 2 | – | – | – | 5,8 | 2# | 400/3/50 | 180 |

| EP 212125 | 219 | 219 | 326 | 183 | 200 | 94×200 | 9 | 4 | 4 | 4 | 2 | 2 | – | – | – | 5,8 | 2# | 400/3/50 | 200 |

| EP 212325 | 219 | 239 | 346 | 183 | 220 | 94×200 | 9 | 6 | 5 | 4 | 3 | 2 | 2 | – | – | 9,2 | 3# | 400/3/50 | 240 |

| EP 212525 | 219 | 259 | 366 | 183 | 240 | 94×200 | 10 | 6 | 5 | 4 | 3 | 2 | 2 | – | – | 9,2 | 3# | 400/3/50 | 260 |

| EP 212725 | 219 | 279 | 386 | 183 | 260 | 94×200 | 11 | 6 | 5 | 6 | 4 | 2 | 2 | 2 | – | 11,4 | 3# | 400/3/50 | 300 |

| EP 213125 | 219 | 319 | 426 | 183 | 300 | 94×200 | 12 | 8 | 7 | 6 | 4 | 2 | 2 | 2 | 2 | 11,5 | 4# | 400/3/50 | 300 |

| EP 213325 | 219 | 339 | 446 | 183 | 320 | 94×200 | 14 | 8 | 7 | 6 | 4 | 2 | 2 | 2 | 2 | 11,5 | 4# | 400/3/50 | 360 |

| EP 213725 | 219 | 379 | 486 | 183 | 360 | 94×200 | 15 | 10 | 8 | 8 | 5 | 2 | 2 | 2 | 2 | 11,6 | 4# | 400/3/50 | 400 |

| Model | External width L [cm] | External depth P [cm] | Door Open Depth W [cm] | Useful Internal Width Li [cm] | Useful Internal Depth Pi [cm] | Doorway L1xH1 [cm] | Rack capacity for 40×60 trays | Rack capacity for 60×80 trays | Rack capacity for 60×80 trays C&G | Rack capacity for 80×80 trays | Rack capacity for 80×120 trays | Rack capacity for 63×180 frames (L=125) | Rack capacity for 63×215 frames (L=160) | Rack capacity for 63×255 frames (L=200) | Rack capacity for 63×297 frames (L=242) | Maximum absorbed power [kW] | Compressor Power (&) [Hp] | Power Supply Voltage [Volt/F/Hz] | Quantità prodotto (*) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EP 251525 | 259 | 159 | 266 | 223 | 140 | 94×200 | 8 | 4 | 3 | 2 | 2 | – | – | – | – | 5,8 | 1,5E | 400/3/50 | 160 |

| EP 251725 | 259 | 179 | 289 | 223 | 160 | 94×200 | 9 | 5 | 3 | 2 | 2 | – | – | – | – | 5,8 | 1,5E | 400/3/50 | 180 |

| EP 251925 | 259 | 199 | 306 | 223 | 180 | 94×200 | 11 | 6 | 5 | 4 | 2 | 3 | – | – | – | 5,8 | 2# | 400/3/50 | 200 |

| EP 252125 | 259 | 219 | 326 | 223 | 200 | 94×200 | 12 | 6 | 6 | 4 | 2 | 3 | – | – | – | 5,8 | 2# | 400/3/50 | 240 |

| EP 252325 | 259 | 239 | 346 | 223 | 220 | 94×200 | 13 | 6 | 6 | 4 | 3 | 3 | 3 | – | – | 9,2 | 3# | 400/3/50 | 300 |

| EP 252525 | 259 | 259 | 366 | 223 | 240 | 94×200 | 14 | 8 | 7 | 4 | 3 | 3 | 3 | – | – | 9,2 | 3# | 400/3/50 | 320 |

| EP 252725 | 259 | 279 | 386 | 223 | 260 | 94×200 | 16 | 9 | 7 | 6 | 4 | 3 | 3 | 3 | – | 11,4 | 3# | 400/3/50 | 350 |

| EP 253125 | 259 | 319 | 426 | 223 | 300 | 94×200 | 18 | 9 | 9 | 6 | 4 | 3 | 3 | 3 | 3 | 11,5 | 4# | 400/3/50 | 400 |

| EP 253325 | 259 | 339 | 446 | 223 | 320 | 94×200 | 19 | 10 | 9 | 6 | 4 | 3 | 3 | 3 | 3 | 11,5 | 4# | 400/3/50 | 430 |

| EP 253725 | 259 | 379 | 486 | 223 | 360 | 94×200 | 22 | 12 | 11 | 8 | 5 | 3 | 3 | 3 | 3 | 11,6 | 4# | 400/3/50 | 480 |

Technical features

- Temperature adjustable from -15°C to +40°C

- Humidity adjustable from 55% to 99%

- White zinc-plasticized interior finish

- White zinc-plasticized exterior finish

- Panel insulation thickness: 80 mm

- Active humidity regulation

- Carriageable Floor 60 mm thickness in high-resistance phenolic resin, with a rough non-slip surface

- Corrosion-resistant aluminum alloy air ducting

- Evaporators of our own development with evaporating coil cataphoresis-treated and AISI 304 stainless steel condensation recovery tank

- Automatic defrosting with heating element

- Stainless Steel AISI 316 Steam Accumulation Generator with heating elements

- Tropicalized refrigeration unit

- Electronic humidifier with immersed electrodes

- Electronic control with 7" touch screen graphic display

- Alaska LEV4 Software

- Cabinet without floor

- Cabinet with front exterior finish in AISI 304 stainless steel

- Cabinet with complete exterior finish in AISI 304 stainless steel

- Cabinet with complete interior finish in AISI 304 stainless steel

- Additional door on the front

- Additional door on the rear

- Silenced and hooded unit

- Tropicalized refrigeration unit, to function in environment up to +43 °C

- Touch screen control panel installed on the door

Our proofers are at your disposal!

You can come to our headquarter and try your recipes working with a laboratory 4.0!

Fill out the form, you will be contacted in no time!