Mini Turbo

Blast chiller / shock freezer for 60x40 trays

Extremely compact Blast chiller / Shock freezer, available in the 5, 10 o 15 trays version. Mini-Turbo is perfect for any kind of professional kitchen or laboratory. Equipped with powerful and easy-to-use touch screen control panel.

Blast Chilling / Shock Freezing advantages

Quickly lowering the temperature of food is a fundamental process for preserving the organoleptic qualities of food for a long time. The rapid cooling of food guarantees the following advantages:

Prevent bacteria proliferation

The temperature range between +65 °C and + 10 °C where the highest bacteria activity can be observed is quickly passed through, thus minimizing proliferation

Preserves food inner structure

In the shock freezing process the water contained in the foods quickly freezes into micro-crystals which do not tear up the inner structure, as a slower process with macro-crystals formation would

Operating modes

By time

Blast chilling / Shock freezing for a set time duration

With core probe

Blast chilling / Shock freezing until the probe at the product core measures the desired temperature

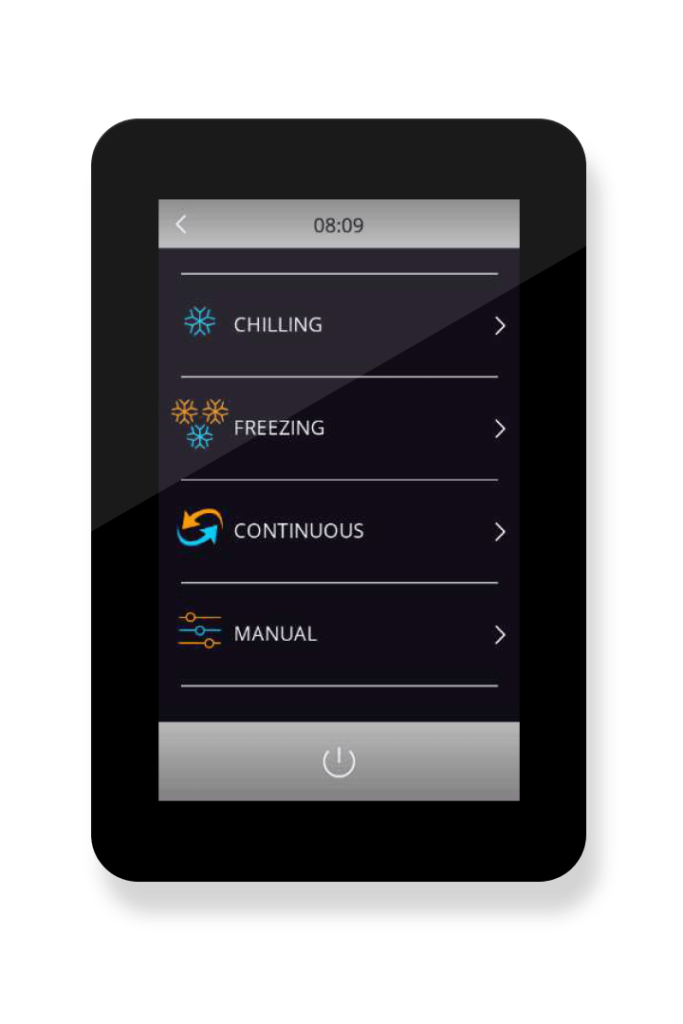

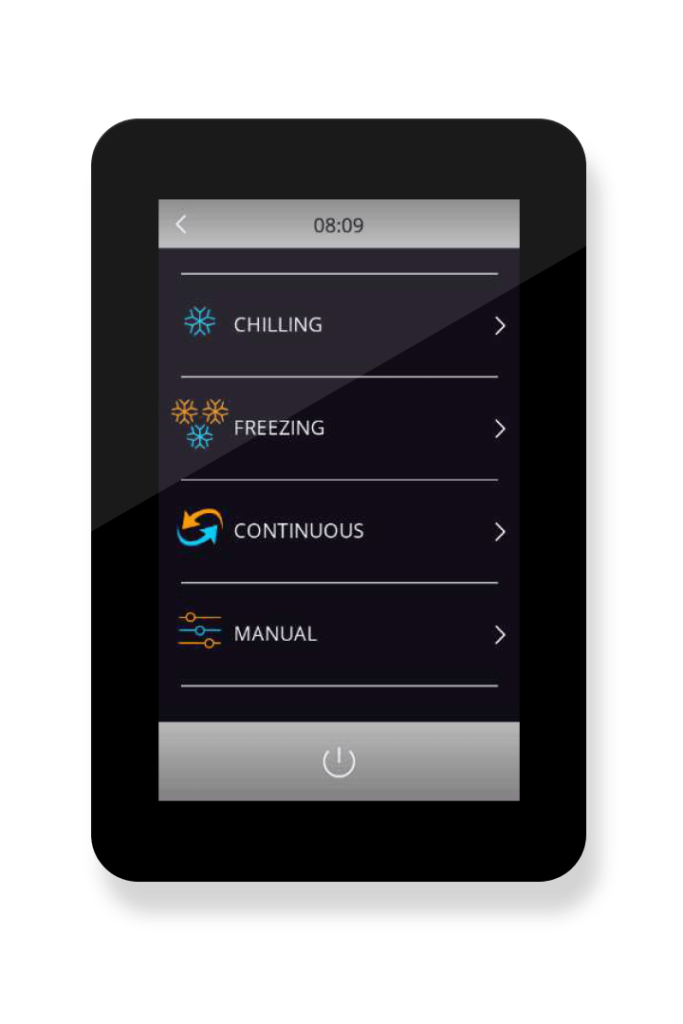

5” Touch screen control panel for Industry 4.0

Equipped with SURG-TOUCH software with:

- Pre-defined Blast Chilling / Shock Freezing cycles

- Work cycle by time or by temperature with core probe

- HARD and SOFT work cycles for blast chilling and shock freezing

- Up to 40 customizable programs

- Automatic switch to storage mode at the end of the cycle

- Adjustable fan speed

- HACCP log, also available for USB download

- Interconnection with external software or web platform

5” Touch screen control panel for Industry 4.0

Equipped with SURG-TOUCH software with:

- Pre-defined Blast Chilling / Shock Freezing cycles

- Work cycle by time or by temperature with core probe

- Modalità HARD per grandi pezzature o SOFT per prodotti delicati

- Up to 40 customizable programs

- Automatic switch to storage mode at the end of the cycle

- HACCP log, also available for USB download

- Interconnection with external software or web platform

Available models

MD5

5 trays 40x60 cm

MD10

10 trays 40x60 cm

MD15

15 trays 40x60 cm

MD20

20 teglie 40x60cm

Technical data

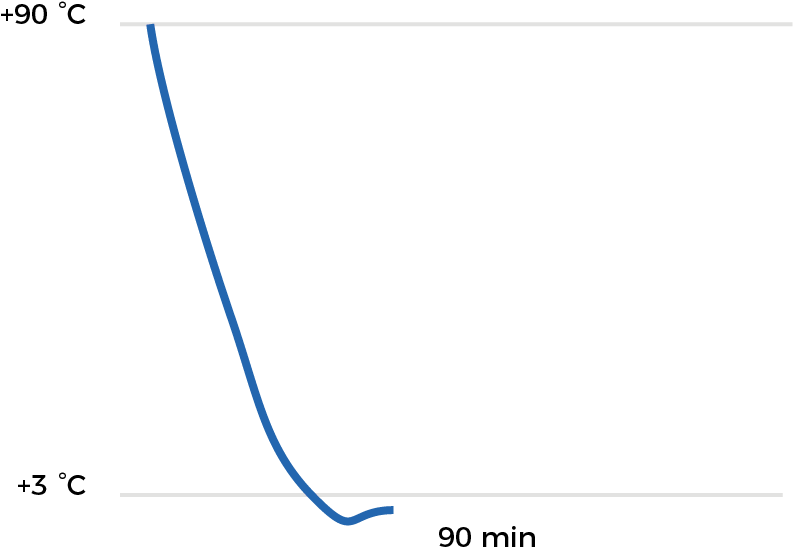

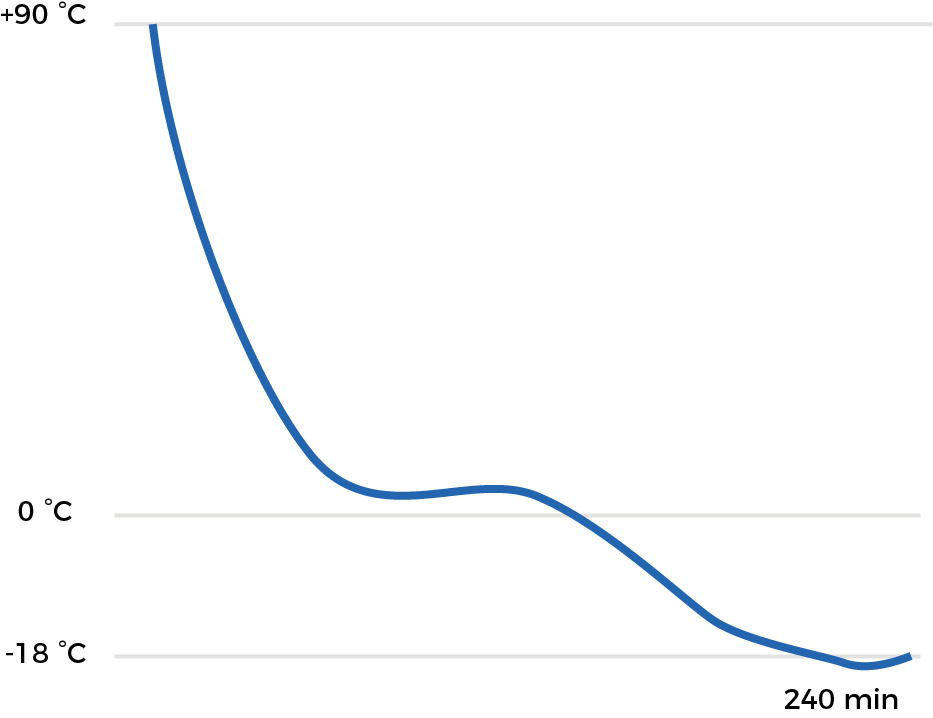

| Model | External width L [cm] | External depth P [cm] | External height H [cm] | 60x40 cm trays capacity (*) | Blast chilling production +90/+3 °C in 90 min [kg] (#) | Shock freezing production +25/-18 °C in 240 min [kg] (#) | Compressor power [hp] | Maximum absorbed power [kW] | Voltage [Volt/F/Hz] |

|---|---|---|---|---|---|---|---|---|---|

| MD 05 | 78 | 80 | 97 | 5 | 20 | 14 | 0,9 | 0,8 | 230/1/50 |

| MD 10 | 78 | 80 | 148 | 10 | 35 | 25 | 1,7 | 2 | 400/3/50 |

| MD 15 | 78 | 80 | 186 | 15 | 56 | 40 | 3 | 3,3 | 400/3/50 |

| MD 20 | 78 | 80 | 220 | 20 | 75 | 55 | 4,0 | 4,1 | 400/3/50 |

Scroll right >>>

(*) With standard equipment of pairs of guides for trays included (arranged with 70 mm pitch), trays not included

(#) Data referred to raw croissant or small-sized breads of 50 grams weight (diameter 2,5 cm)

Technical features

- One-piece construction in AISI 304 stainless steel

- High-density insulation thickness of 60 mm

- Evaporator treated with anti-corrosion paint

- Evaporator easily accessible for cleaning and maintenance

- AISI 304 stainless steel racks and guides

- Rack pitch: 17.5 mm

- Interior fittings for GN1/1 and EN60x40 trays

- Automatic hot gas defrosting

- Internal tank bottom with drain

- 5'' touch screen control panel

- Pairs of stainless-steel guides for the specified trays capacity

Our proofers are at your disposal!

You can come to our headquarter and try your recipes working with a laboratory 4.0!

Fill out the form, you will be contacted in no time!