Tornado

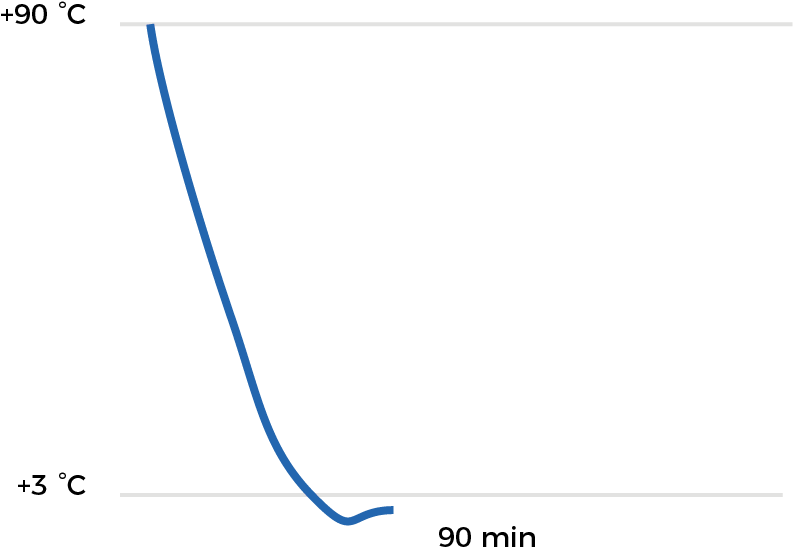

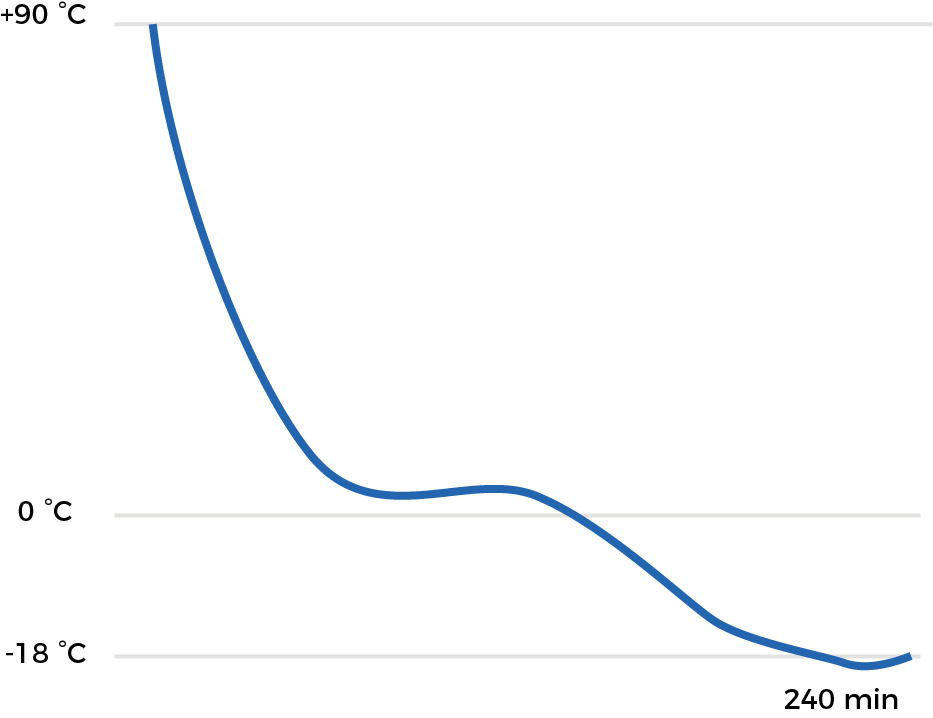

Blast chiller / shock freezer for 2 trolleys 60x40

Extremely compact Blast chiller / shock freezer for trolleys. Available in the 60 or 80 kg/hour versions (production in shock freezing from +25°C to -18°C)

Blast Chilling / Shock Freezing advantages

Quickly lowering the temperature of food is a fundamental process for preserving the organoleptic qualities of food for a long time. The rapid cooling of food guarantees the following advantages:

Prevent bacteria proliferation

The temperature range between +65 °C and + 10 °C where the highest bacteria activity can be observed is quickly passed through, thus minimizing proliferation

Preserves food inner structure

In the shock freezing process the water contained in the foods quickly freezes into micro-crystals which do not tear up the inner structure, as a slower process with macro-crystals formation would

Operating modes

By time

Blast chilling / Shock freezing for a set time duration

With core probe

Blast chilling / Shock freezing until the probe at the product core measures the desired temperature

5” Touch screen control panel for Industry 4.0

Equipped with SURG-TOUCH software with:

- Pre-defined Blast Chilling / Shock Freezing cycles

- Work cycle by time or by temperature with core probe

- HARD and SOFT work cycles for blast chilling and shock freezing

- Up to 40 customizable programs

- Automatic switch to storage mode at the end of the cycle

- Adjustable fan speed

- HACCP log, also available for USB download

- Interconnection with external software or web platform

7” touch screen control panel for Industry 4.0

Equipped with SURG-TOUCH software with:

- Pre-defined Blast Chilling / Shock Freezing cycles

- Work cycle by time or by temperature with core probe

- HARD and SOFT work cycles for blast chilling and shock freezing

- Up to 40 customizable programs

- Automatic switch to storage mode at the end of the cycle

- Adjustable fan speed

- HACCP log, also available for USB download

- Interconnection with external software or web platform

Available models

TO 60

60 kg/h shock freezing

TO 80

80 kg/h shock freezing

Technical data

| Model | Blast chilling production +90/+3°C [kg/h] (*) | Shock freezing production +25/-18°C [kg/h] (*) | Capacity of trolleys for trays 40x60 cm [n] | Capacity of trolleys for trays 60x80 cm [n] | Internal width Li [cm] | Internal depth Pi [cm] | Internal heigth Hi [cm] | Doorway L1xH1 [cm] | External width L [cm] | External depth P [cm] | External height H [cm] | Maximum absorbed power [kW] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TO 60 | 100 | 60 | 2 | 1 | 80 | 100,8 | 200 | 80×190 | 106 | 166 | 228 | 5,4 |

| TO 80 | 140 | 80 | 2 | 1 | 80 | 100,8 | 200 | 80×190 | 106 | 166 | 228 | 6,1 |

Scroll right >>>

(*) Data referred to raw croissant or small-sized breads of 50 grams weight (diameter 2,5 cm)

Technical features

- AISI 304 Scotch Brite stainless steel interior finish

- White zinc-plasticized exterior finish

- Panel insulation thickness of 100 mm

- Carriageable floor with interior finish AISI 304 stainless steel in acciaio inox AISI 304 2B

- AISI 304 stainless steel access ramp

- Cataphoresis-treated evaporator

- Evaporator easily accessible for cleaning and maintenance

- Automatic hot gas defrosting

- AISI 304 stainless steel perimeter bumpers

- Electronic control with 5" touch screen display installed on the door

- Software: SURG-TOUCH

- Stainless steel exterior

- AISI 304 Scotch Brite stainless steel front

- Water condensation

- Shipment with disassembled cabinet

- Tropicalized condenser

- Silenced and hooded unit

Our proofers are at your disposal!

You can come to our headquarter and try your recipes working with a laboratory 4.0!

Fill out the form, you will be contacted in no time!